- 086 18660174681

- pclmachinery@outlook.com

This high-efficiency production cell integrates three critical processes—assembly, submerged arc welding, and flange straightening—into a single workstation. It optimizes floor space, minimizes material handling, and significantly reduces labor intensity for H-beam and T-beam fabrication.

| Flange Width | 150-800mm | Workpiece Height | 200-2000mm |

| Flange Thickness | 6-40mm | Workpiece Length | 4000-15000mm |

| Web Height | 200-1800mm | Welding Speed | 150-1500mm/min |

| Web Thickness | 6-32mm | Main Machine Power | 17.5kW |

| H-Beam Length | 4000-15000mm | Roller Conveyor Power | 0.75*4=6kW |

| Assembly & Welding Speed | 200-2000mm/min | Flux Recycling Power | 3*2=6kW |

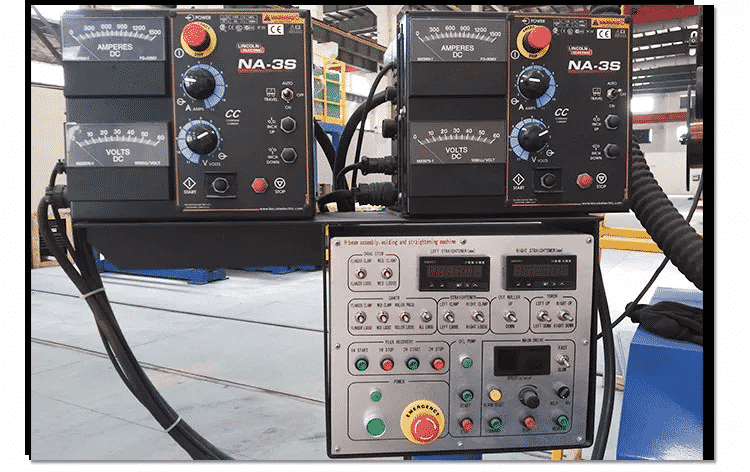

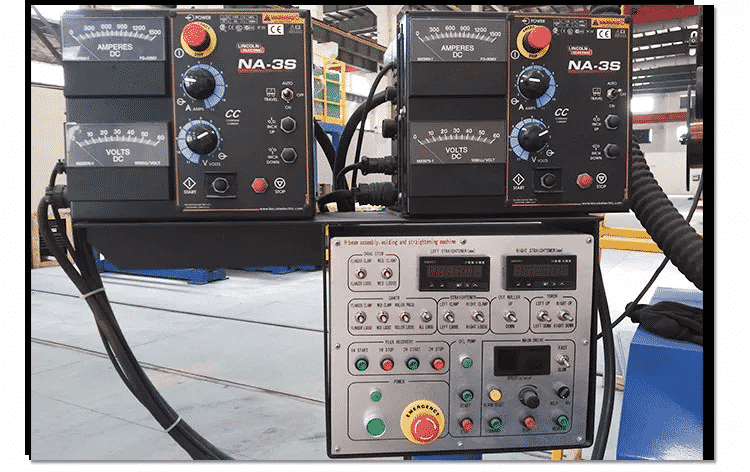

| Pump Station Power | 4kW | Welding Source Power | 138kW (69kW*2) |

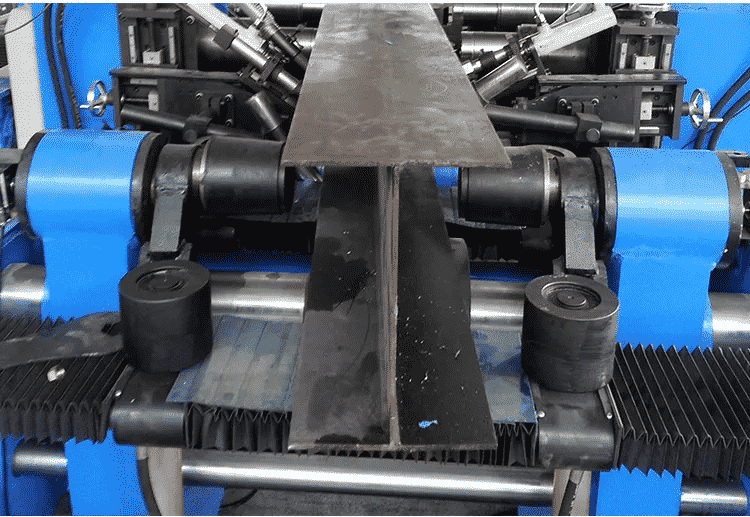

Features an automated centering and positioning system for web and flange plates, ensuring superior fit-up accuracy and structural stability.

The 2-axis adjustable welding gun mounts allow for precise positioning and angular control, ensuring high-quality weld beads and deep penetration.

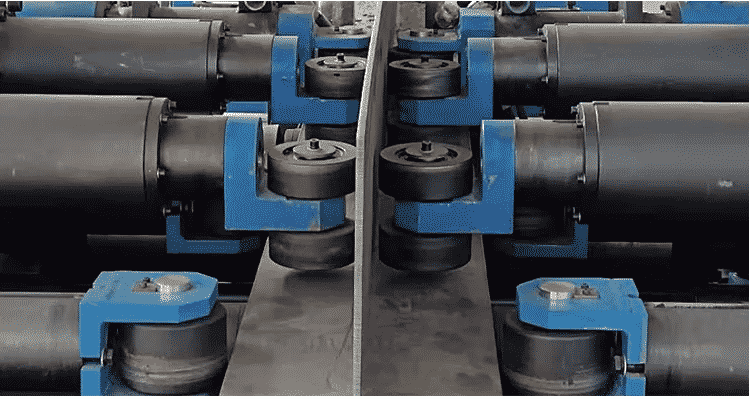

Unique hydraulic correction rollers rectify flange deformation without blocking the operator’s view, facilitating real-time quality monitoring.

The main unit can be decoupled from the straightening auxiliary to operate independently as an assembly or welding station as needed.

Built with imported linear guideways, the system maintains a machining tolerance of 0.02-0.03mm (2-3丝) for every beam produced.

Advanced inverter welding technology provides 25%-35% energy savings, significantly reducing long-term operational costs.